Categories

- Raw Wood Veneer

- Paper-Backed Veneer

- Edge Banding

- Vacuum Press Items

- Veneering Supplies

Shop by

Veneer Species

Veneer Supplies Newsletter

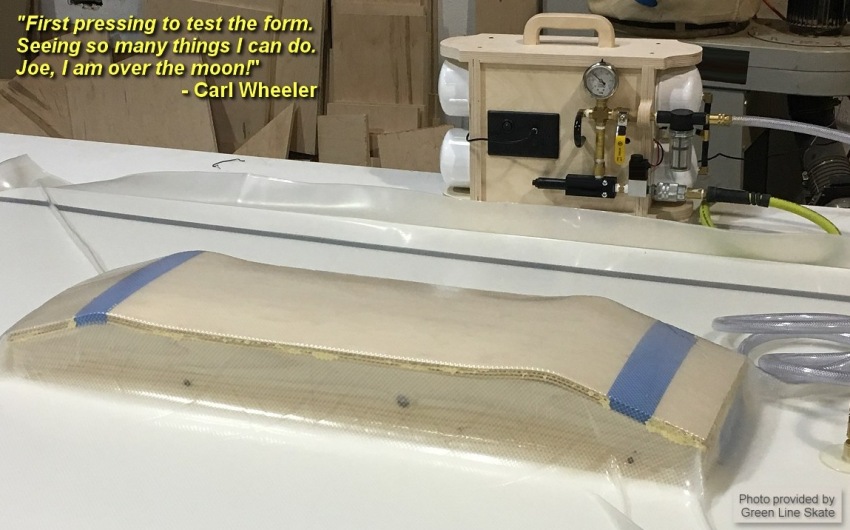

With the Project: V4™ kit and our simple step-by-step assembly instructions, you can build an auto-cycling vacuum press powered by your air compressor. The most significant improvements over the previous version of the system are the simplified wiring process (now 12v DC) and the new vacuum manifold assembly. This is the best vacuum press kit we've ever offered.

No Additional Parts Needed

Everything you see in the picture is included with the V4 kit. This includes the redesigned carrier assembly made from finish-grade birch plywood, as well as the high-flow vacuum filter and our quick-connect vacuum fittings. We also include the power cord and handle. PVC cement is not included, but it's readily available at most hardware stores.

How It Works

This vacuum press uses your air compressor to create vacuum for veneering and clamping. The system automatically shuts off air-flow to the vacuum generator (also called a venturi) when the desired vacuum level is reached, so your compressor does not run continuously. No modifications are done to your air compressor. The flow of compressed air stops when adequate vacuum is created within the V4 system. Your compressor will only turn on as air is needed to refill its tank.

Kit Instructions: Click here (free PDF download)

Vacuum Press FAQ: Click here

Kit Contents

Vacuum Parts

|

Brass Fittings

|

| Project: V4™ Version |

Vacuum

Flow |

Air Demand

@ 80 PSI |

Air Demand @ 90 PSI |

Maximum

Bag Size |

| Mini™ | .5 CFM | .8 CFM | 1.2 CFM | 2' x 4' |

| Basic™ |

1.2 CFM

|

1.8 CFM

|

2.2 CFM |

4' x 4'

|

| Plus™ |

3.2 CFM

|

4.8 CFM

|

5.5 CFM |

4' x 9'

|

| Premium 5™ | 5.5 CFM | 7.8 CFM | 9 CFM | 4' x 15' |

| Premium 9™ | 9 CFM | 12.5 CFM | 14 CFM | 6' x 15' |

Project: V4™ Features

Simplicity: The entire system can be built in less than 2 hours. You will find the process of building your own vacuum press very rewarding. No soldering or advanced electrical skill is required to assemble the system. The electrical wires have the connectors already attached!

Simplicity: The entire system can be built in less than 2 hours. You will find the process of building your own vacuum press very rewarding. No soldering or advanced electrical skill is required to assemble the system. The electrical wires have the connectors already attached!

Strength: This system is capable of generating up to 1,785 lbs of pressure per square foot at sea level using a very powerful venturi that comes with a lifetime warranty.

Easy Assembly: The V4 kit was designed for quick assembly, and the kit instructions are the best I've ever offered. It's a free download, so you can check it out before ordering.

Vacuum Storage: The vacuum valve allows the system to be pre-charged with vacuum to increase the initial pull down speed.

Adjustability: The vacuum controller has an adjustment screw that allows you to dial in your desired level of vacuum. You'll find that 21" of Hg is ideal for most veneering projects. The system is adjustable from 10.5" to 25.5" of Hg. An alternate vacuum controller for low vacuum applications is available here.

Speed: The Project: V4 system will create vacuum slightly faster than previous versions of our venturi system due to an improved pneumatic design.

Air Efficiency: The venturi component is precision-milled in the USA and designed with strict efficiency requirements. This means even smaller compressors can pull down average size vacuum bags.

Electrical Efficiency: The system runs on 12v DC and uses less than 6.5 watts when the system is recharging vacuum. The V4 system draws no power when it cycles off. Keep in mind that the electrical consumption of your air compressor will vary.

Quality: Each part of the V4 kit has been selected for durable and reliable operation. Many of the core components have been used in our other kits for more than 10 years.

Power Supply Option

The V4 kit comes with an 8-foot 120v AC power adapter for US and Canada power outlets. Though we no longer ship overseas, you can select the option for a 5-foot 240v AC power adapter suitable for AU, EU, and UK power sources.

![]() WARNING: This product can expose you to chemicals, including lead, which are known to the state of California to cause cancer and birth defects or other reproductive harm. For more information, visit www.P65Warnings.ca.gov.

WARNING: This product can expose you to chemicals, including lead, which are known to the state of California to cause cancer and birth defects or other reproductive harm. For more information, visit www.P65Warnings.ca.gov.

Questions & Answers

Will air continuously flow from the air compressor after the full vacuum is drawn on the project?

No. Air stops coming from the compressed air source when the vacuum controller reaches its cut-off setting. Air flow from the compressor only happens when the vacuum controller opens the air valve on the system to build or replenish vacuum in the system.

Which version of the V4 kit will work with my air compressor?

Refer to the owner's manual that came with your air compressor to find its CFM rating. Then compare that rating to the chart shown in the product description for this kit. Your compressor must be able to meet or exceed the CFM requirements of the V4 version that you are considering. There is no harm if your compressor's output is far greater than what the venturi requires.c

My air compressor is rated in SCFM. How does that compared to CFM?

The formula to convert SCFM to CFM is complicated. If your compressed air is around 68°F and has a relative humidity of 36%, then SCFM and CFM are approximately the same. However, I recommend estimating this cautiously, so it may be best to multiply your SCFM rating by .95 to get a reasonable expectation of CFM. Click here if you really want to know more about this.

What can I do if my air compressor falls short of the requirements for the venturi?

The system will not work if your air compressor can not create the required air flow for the venturi. In this case, the venturi will only achieve partial vacuum. Some users have reported that the "work-around" found at this link helps if the air compressor is slightly under-powered.

Can I upgrade from the Mini, Basic, or Plus version to the Premium 5/9 version at a later time?

Yes, but it requires several parts; some of which are a bit expensive. However, keep in mind that the vast majority of users find the Plus version more than adequate for most projects up to 4x9, so upgrading may not be necessary.

Will this system have enough force to bend strips of wood so I can make bent laminations?

This is a difficult question to answer because it depends on many factors such as thickness, species and grain direction. It will also depend on the radius and complexity of the curves that are being used on the project. At sea level, a vacuum press can create up to 1,750 lbs of clamping pressure per square foot. You will need to decide if that is enough for your bending project. Others have had success in doing this.

Are the assembly instructions included with the V4 kit?

I do not include printed instructions with the kit because it's too wasteful. Most people have already printed and read the assembly instructions before they order... something I highly recommend.

Does the V4 kit include a vacuum pump?

This system uses a venturi unit to create vacuum with compressed air. It does not include or use a vacuum pump.

Does the V4 kit include an air compressor?

The kit includes everything shown in the main picture of this system. It does not include an air compressor.

Can I order the kit without the venturi?

I can not remove parts from this kit for a variety of reasons. I have no way to know that the parts you may substitute will fit on the carrier or if they will work with the other pieces in the kit. For example, there is no way for me to know if the air valve on the V4 kit can supply enough air flow to a substitute venturi. That is just one example of many. Additionally, I want to provide support in the event that the kit doesn't work correctly and that is impossible when substitute parts are used that I can not evaluate for compatibility. Lastly, removing a part from the kit would not save very much money since the kit is heavily discounted due to being offered as a complete package of parts. Think of it as a bulk discount.

Can I order this kit without the carrier?

This kit is not available without the carrier, but you might want to consider ordering the Project: V2 kit instead.

I already have some parts on hand. Can I order this kit without those parts?

This product is only sold as a complete kit. I can not offer a version without each piece that is included with the kit.

What is the size of assembled V4 kit?

Approximately 18-3/4 x 12-1/2 x 8-1/4" (WxHxD)

Can I use this system with epoxy?

The V4 kit is not designed for use with epoxy, however I have not heard from any users that doing so caused an issue with their vacuum press.

Can this system be used for carbon fiber work?

I honestly don't know the answer to that question. Many have asked about it and then bought the system. I haven't received any feedback from them. If you have used the system for a carbon fiber project, feel free to send me some details.

Can I use a vacuum press for clamping boards together face to face?

At sea level, a typical vacuum press can put down the equivalent of 1,750 lbs of pressure per square foot. If the boards are flat, then this is generally considered more than adequate for a project where two sheet materials such as plywood or MDF are being glued together face to face. This also is true for gluing solid wood boards together.

How does my altitude affect the maximum vacuum level of this system?

There is a loss of approximately 1" of Hg for every 1,000 feet above sea level. For example, at 5,000 feet above sea level, the most vacuum this system will create is 20.5" of Hg. The generally accepted minimum for vacuum pressing most veneers is 17" of Hg, but a few species such as maple and bubinga are best pressed at 21" Hg. Since this system has a maximum vacuum of 25.5" Hg at sea level, it is not suitable for users above 8,000 feet.

How much does the system weigh?

The complete system weighs approximately 18 lbs.

What power source is required?

The Project: V4 kit requires standard US 120v AC. The system uses a power adapter to supply the system components with 12v DC.

Can I get the drawings for the wood carrier so I can make my own?

I don't offer a set of drawings for the kit, since it is not sold without the carrier.

Why does the venturi require more CFM at higher PSI? Shouldn't it be lower CFM at higher PSI?

We have two topics that are being co-mingled. The first is how much air flow can a compressor generate when the flow is unrestricted, and the second, how much air is flowing out of the compressor when it is connected to a device that restricts its flow.

This question makes a valid point about compressors having higher output flow rate (CFM) at lower pressures. The key to this are the conditions where this is true. Higher flow rates at lower operating pressures result from having little to no restriction on the output of the compressor. As the restriction increases, the pressure in the compressed air line will increase and the flow decreases.

When air leaves a compressed air line and shoots unrestricted into the atmosphere, the pressure in the air stream, once it exits the compressed air line, is 0 PSI. To prove this, place a "T" fitting at the exit of the compressed air hose and place a gauge in the leg of the "T" that is 90 degrees to the axis of flow. Provided that the through bore diameter of the "T" is the same size or larger than the inside diameter of the compressed air line, the gauge will read 0 PSI. If you place a ball valve on the outlet side of the "T" and slowly close the valve, you will see the gauge show increased pressure and the amount of air leaving the "T" will decrease. Once the ball valve is fully closed, the gauge will show full pressure and no air will be flowing out of the "T".

When there is a venturi at the end of the compressed air line, a very different condition is created than what is noted above because the air is not allowed to exit freely to the atmosphere. The venturi has a limiting orifice which presents a significant restriction, like the ball valve in the example above.

When a venturi is connected to the compressor, a specific amount of compressed air will pass through the limiting orifice inside the venturi. When the input pressure is increased, more compressed air will flow through that orifice because there is more force being applied to each air molecule, which results in more air molecules fitting through the orifice.

In summary, when there is a restriction in the system, a higher compressed air pressure will result in more compressed air leaving the compressor. The compressor will not produce more flow at higher pressures, however more air will leave the compressor and flow through the venturi.

If the previous system was called Project: V2, then why is this not called Project: V3?

We did have a Project: V3™ kit a few years ago, but one of the key component suppliers went out of business. It was a short-lived system, in which I may have only shipped 20 to 30 units. If you are one of the lucky few that has the V3 system, you've got a great tool in your shop!

Product Reviews

-

A Vacuum Press for The Rest of Us

Review by Nick Miller

Rating:

I want to thank the good people at Veneer Supplies for the vacuum press and the 30 mil polyurethane bag (with breather fabric). Without their help and encouragement I could never have finished our kitchen project. It was incredibly satisfying to see panels come out of the bag because they were all flat, smooth, and bubble-free. The owner of the company answered all of my pre and post sale questions. They have earned my trust and respect. I'm looking forward to placing my next order for a whole lot of walnut burl.

-

Great Product and Great Value

Review by Milton McClaskey

Rating:

The instructions for building the [Project:V4] system are extremely clear and easy to follow - though I confess I did print them out rather than take my laptop into the shop! - and the finished product works better than I'd hoped. I was worried that my compressor would be running at capacity and that I'd regret not spending the additional money to get a 'stand alone' system but that's not the case. Very happy with the whole process: ordering was easy, the product arrived quickly, communications were timely and appropriate, everything was properly packed and well labeled, assembly was straightforward and fun (because the instructions were so very clear and explicit), and it works exactly as it's supposed to. Zero complaints.

-

Veneering is Awesome!

Review by Mark Baber

Rating:

This is an economical alternative to buying the dedicated vacuum pump. Since I have an air compressor I thought I would try the project V4 kit. I had veneered a panel just using clamps and platens and didn't enjoy the process even though it turned out good. I received the kit and put it together easily plus it was fun seeing it come together perfectly with the help of the best assembly directions I have ever used! With the bag and mesh I ordered with it I veneered my first panel and was amazed at how quickly it took all the air out of the bag. It held pressure all night. Love it!

-

Quick Build, Excellent Kit

Review by Michael Liechty

Rating:

The kit was delivered quickly and was well packaged. As other reviewers have already mentioned, the instructions (online) were very thorough and easy to follow. I had the press built in around 2 hours and it held a vacuum for over an hour without having to cycle back on a second time. Very impressive! Looking forward to using it to refinish some damaged chairs.

-

Very Nice Kit

Review by Thomas Penrose

Rating:

Very nice kit with good assembly instructions. The pump has worked great with my 4x9 vacuum bag. The instructions were very detailed, but it is important you read each step carefully to avoid damaging a part.

-

Now here's a use I'll bet you never thought of before...

Review by Dave Desertspring

Rating:

I bought this kit to use for vacuum filtering my homemade shrubs that I mix with sparkling water. Gravity filtering just didn't work. With this Venturi Vacuum pump hooked up to my 60 gallon Porter Cable air compressor I can generate plenty of vacuum. I use it with a1 liter vacuum flask and filter setup. Now I can filter my shrub mixtures to clarity within a minute or so.

The kit was easy and fun to assemble. I finished the box with a couple coats of clear Watco before assembly. Works perfectly. Next up: try it out for some woodworking veneering projects!

-

Project V4 Vacuum Press kit

Review by John Edgar

Rating:

I purchased the Project V4 based on the description and suggested use. It fit for what I have planned I'm a hobbyist/DIY;and didn't want to spend $$$ on a vacuum pump. I have a compressor already. The assembly instructions, for me, were simple and straightforward. I read through all the instructions before starting, and if you follow the suggestions, you will be successful. I took the time to stain and finish the wood. I painted the PVC because the white is ugly. At startup, the pump pulled 23.5" of vacuum. It stayed the there for an hour. I'm very satisfied with this pump. Now I can veneer lots of curved surfaces. I'm probably done with contact cement veneer work.

-

Well Designed

Review by Greg Kraning

Rating:

Assembled easily. Well designed. Had an issue with the controller but the instructions warned me in advance. A metal component may have been better for my heavy hand. With the replacement part in hand completion and start up was easy. I don't have a lot of experience with it yet, performance has been flawless.

[Note from Joe: Greg is referring to the vacuum controller. The maximum torque that can be put on this is 4 in-lbs. That isn't much and when more force is used, the part can break. Luckily, replacements are not that expensive. And switching to a metal-body vacuum controller would add $90 to the kit cost.]

-

A Fun Science Project Becomes a Piece of Shop Machinery

Review by Laron Algren

Rating:

At first, the premise seems too good to be true. However, if you follow the carefully crafted instructions, you will be rewarded with a very capable vacuum pump. Caution: try not to drop your vacuum gauge on a concrete floor. The impact may render it useless and in need of replacement.

-

Maximum Vacuum From Something So Simple!

Review by Ron Payton

Rating:

I have a 50 gallon compressor in my workshop so the Project V4 kit was a no-brainer. Assembly could not have been any easier thanks to the kit instructions being written so clearly. For 300 bucks, I got an auto-cycling vacuum press that makes 1,700 lbs of pressure PER SQUARE FOOT! The owner of this website is very helpful too. I sent an email to him when I ran into a small question about the assembly and he replied within a few hours and on a Saturday. Customer service like this is nearly extinct these days, but this site is the exception. Great experience, great prices, great shipping, great everything.

-

Perfect Solution

Review by Chuck Marfione

Rating:

I had been looking for oilless vacuum hold-down solution for use with my CNC machining operations. The V4 tuned out to be the perfect solution. I've always been skeptical of venturis and their ability to supply enough vacuum to safely hold material in place. The V4 system works flawlessly with my 20-gallon compressor, couldn't be happier. The kit was very easy to assemble and the instructions were better than I would have expected. No need to scratch your head trying to figure out what you need to make a venturi work for you. All you need is the V4, a decent compressor, and an afternoon and you'll be up and running. Joe's done all of the hard work. If you add up all of the time and aggravation of collecting all of the parts you'll soon find out that the V4 is definitely a time and money saver. Buy it...it's worth every penny!

[Note from Joe: I suspect the suitability of the V4 kit for CNC clamping depends on many, many factors so I cannot guarantee it will work for all CNC applications.]

-

Straight Forward Instructions

Review by Hassen Butler

Rating:

I finally assembled my V4 vacuum press kit. The instructions were straight forward and I did not have any problems during assembly. The ordering process was easy and the delivery was fast. All said I am happy with my purchase.

-

Look No Further

Review by James Ott M.D.

Rating:

I have been looking at vacuum pumps for over a year. I wanted one that would be able to handle veneering projects but also would be able to seal mason jars for food storage. Many of the pumps that I looked at were poorly built, broke easily, or just would not achieve the vacuum that I was looking for. This pump and company were just incredible. I read that instructions that said assembly time of 2 hours. I thought yeah for a guy who has assembled 5-10 of them. So I timed myself. It took me 2 hours and 10 min. The instruction are the best I have ever seen for any project.

But you don't buy it for the assembly instructions, you buy it for its ability to achieve a vacuum. This pump with achieve 24" Hg easily. It is quiet, easy to use, and has virtually no moving parts. If you are hesitating as I did for over a year, don't. Just buy it. You will not be disappointed.

-

Awesome Kit with Quality Parts

Review by Flint Connor

Rating:

I can't say enough good things about the company. They were very helpful when I asked questions about picking the right vacuum press for my workshop. When I ordered, they packed and shipped it right away - the box arrived at my house less than 24 hours after I ordered! I went with the V4 kit which is a marvel to observe in action. The kit was packed well and all of the parts were high quality. I couldn't ask for a better experience buying from Veneer Supplies.

-

Exceeded My Expectations

Review by Giovanni Villella

Rating:

I just wanted to add a short note about the quality of instruction that comes with V4 Venturi Kit - It's brilliant. The level of detail in the way the plywood has been cut is critical, just the perfect amount of space has been thoughtfully designed for my kit to look & perform like the one that Joe built. Highly recommend if it if your looking at this kit. 10/10 - Thanks Joe!!

-

Great Project and Even Better Product

Review by Garrett Roberson

Rating:

I was slightly skeptical when buying this kit because anyone I spoke to about getting into vacuum veneering suggested the more expensive off the shelf pumps, but since I have a nice compressor already and have some experience with venturi's in my day job I figured it was worth a shot.

This is a great kit. It's easy to assemble and takes about 90 minutes or so if you take your time but could be done faster if need be. The fit of everything is great and the final product is equally good. For smaller panels and things like that the draw down is fast. If you get into something larger like a 74"x24"x4" curved piece I'm working on currently the draw down takes a bit of time but nothing that interferes with the build. Once its at full vacuum it cycles occasionally but it's quiet and not a bother at all.

-

Kid Approved

Review by Jason Evans

Rating:

I tasked my 12-year-old with assembling this kit while I did other tasks in the woodshop. Aside from my assistance with PVC gluing (and with the test procedure that the manual suggests having a helper for), he did everything completely independently. And it even works! We tested the vacuum by pressing some packing paper and it worked well. The only real surprise to me is how little air is used (for the Plus model); it makes me wonder if one of the larger Premium models would have worked even though my air compressor doesn't quite meet the requirements.

[Note from Joe: The only factor in determining which version of the V4 system is suitable is the CFM rating of the air compressor. If the compressor doesn't not meet the requirements shown on the chart on the V4 kit page, then it will not draw full vacuum.]

-

Great Venturi Vacuum Kit

Review by Mike Brogan

Rating:

Great kit! We’ll thought out and everything was there, even the Teflon thread tape. Instructions were right on, clear, and easy to follow. Took about an hour and a half to assemble. Had a little trouble with a sticky air valve but a couple of emails back and forth with Joe and the problem was solved. Joe is a man of his word. Very quick response to my questions. Wish other companies had that sort of customer support. Thanks Joe!

-

Great Vacuum Press

Review by John Moore

Rating:

This is a great vacuum press. I bought the kit and it performed beyond what it stated. I used the system to veneer quilted maple veneer to a guitar body and the results were outstanding!!!

-

This Changes Everything!

Review by Garrett Karczewski

Rating:

The team in my cabinet shop had been wanting a vacuum press for several years so we could get away from using expensive paper-backed veneer and contact cement on big commercial projects. We do a lot of high end office cabinetry. The biggest hurdles were finding a system that fit our budget and finding a company we could trust for support and general customer service. One of our staff members found this Project V4 kit and showed it to the other guys. They ended up coming to me and suggesting that we buy the Plus model.

With 4 intelligent and hyperactive personalities, they had the kit assembled in less than an hour. It recharges very infrequently and when it does, it's only on for about 10 seconds or less. The kit parts are very good quality and we're very happy with the purchase. And since we have a good number of uses for the vacuum press, I agreed to buy another one (Premium 5) last month. We now run these presses at least once a day and often dozens of times a day. The companion vacuum bags are rugged and have a good seal when closed properly. We opted for vinyl bags in 2x4, 4x4, and 4x8 sizes. They are a bargain.

The customer service here is second to none. The great communication from the owner is a highlight of the buying experience. He answers questions politely and promptly. Can't say enough good things about our experience with Veneer Supplies. Also, we bought the Better Bond X-Press glue. It is the best out there.

-

100% Successful

Review by Rob Hughes

Rating:

After a year or two of reading about vacuum clamping on the net I purchased the V4 Press Kit, VS Extreme bag, breather mesh and Ultra Cat glue. Any questions regarding what to purchase were promptly answered and after purchasing the products I was kept informed regarding delivery dates.

The products arrived in excellent condition, and the V4 kit went together easily. The parts are of exceptional quality and the instructions are brilliantly written.

The bag is robust yet flexible, easily conforming to complex shapes. My first attempt at vacuum clamping was 100% successful, no leaks, and easily handle by my pancake compressor.

5/5 stars for customer service, product design, value, and overall experience. Thank you.

-

Highly Recommended for Veneering

Review by Brian Harper

Rating:

The V4 press kit amazes me when its in action and I'm still thrilled to watch it pull such a powerful vacuum on my bag. I would not have guessed that compressed air could be used this way... and with no moving parts! The concept and the design is unbeatable. Highly recommended if you want to bring your woodworking to a whole new level of quality and appeal.

-

Quality Product and Parts

Review by Pete Baxter

Rating:

Clear specific and easy to follow instructions. Instructions seem daunting at first blush but aren’t. Should have purchased sooner.

-

This is a Good Option

Review by Craig Creasman

Rating:

Very straightforward project to construct. Excellent quality materials and detailed instructions. Works well. Saves a lot of money over buying a pump as long as you have compressed air in your shop.

-

Very Pleased

Review by Rich Tomasello

Rating:

I ordered a V4 Plus press during the Black Friday promotion and could not be more pleased. Been messing around with shop-made presses, without good results for many years. I got around to pressing my first panel today, book-matched burl walnut. Flawless! along with the press, I ordered the other gear needed (bag, glue, glue roller, etc) and everything came promptly and in good shape. As far as cost, I looked everywhere and Veneer Supplies cannot be beat. Then there is all the information on Joe’s site, what a resource! If you need to know, just look, its there. Thanks Joe and Christine. I will be ordering again soon.

-

Fun Project and High Quality

Review by Dean Cruse

Rating:

This was my first time veneering and the details on the site led me to pick the V4, which I think will be perfect for my needs. The kit was beautifully packaged and the instructions were awesome - detailed and easy to follow. Making the press was a blast, and the quality is excellent. I've done 20 panels so far, and it works great. Highly recommend.

-

Tremendous bang for the buck!

Review by Terry Bakewell

Rating:

This kit is extremely well thought out, very easy to assemble, and gets you into vacuum bagging at an affordable price point. Everything you need to assemble the kit is included except the PVC cement and the air compressor. If you already own a compressor, this is definitely the way to go.

-

Easy Assembly

Review by Steve Rogers

Rating:

This kit is well made and easy to assemble. The instructions were easy to follow and clearly illustrated. It took me about two hours to assemble. It holds 26" Hg with no leak down.

-

Incredible Kit

Review by John Fuda

Rating:

This is an incredible kit. It is extremely well thought out and the instructions could not be clearer. I enjoyed building it and the performance when coupled with the vacuum clamping add-on, a set of Podz, and my nearly silent California Air Tools compressor is amazing. I've used a vacuum pump in the past and this is so much more pleasant to use - quiet and without the oil mist the pump left in the air.

-

Super System!

Review by Steve Smith

Rating:

This V4 kit is excellent. If you already have an air compressor, this is the way to go. This auto-cycling venturi system (using a check valve, electric air valve, and vacuum controller) works perfectly and requires only a minimal amount of compressed air to maintain the vacuum in a well sealed vacuum bag.

Shipping was super quick. Instructions (available online here) were complete and very well written. Assembly time was minimal, although I did take extra time to put a coat of finish on the wooden carrier prior to assembly. I am also going to attach some rubber feet to the bottom but it works just fine without them.

Besides veneering, I also plan to use this system for vacuum chucking on my lathe.

Highly recommended!

-

Fast and Efficient

Review by Nathan Sutti

Rating:

I bought this system and could not be happier. I actually use the system within the orthotic and prosthetic industry and wow what a great product. I would recommend this to anyone looking for a reliable, fast and efficient vacuum system.

-

Worth the Money

Review by Dave Banitt

Rating:

Setup was easy, directions worked like a charm. And the vacuum press worked great! Shipping was also very quick. This is definitely worth the money.

-

Awesome Kit!

Review by John Kuhn

Rating:

Awesome kit! I am building a guitar and wanted to press laminates for the sides and top/back to recreate a famous design. Thank you for being so thorough with the directions and your attention to detail, all the CNC milling was nice and every part was included. The kit took me maybe 2 hours to build, taking my time. It's really airtight, mine lost no more than 1" Hg after 4 hours, and I am confident I could leave my compressor on all day and it would never kick in. Really looking forward to all the fun things I can do with it!

-

Very Pleased

Review by Ezekiel Arena

Rating:

What a great kit to assemble. It is very easy to put together due to the fact that there is a well written and thought out set of instructions. This V4 unit works very well and very pleased to own it. When I assembled the V4 kit , there was a missing part. All it took was one email and had the part a day later.

-

Great Kit - Highly Recommend!

Review by Kevin Griggs

Rating:

This kit is a great option for getting a vacuum press. I originally planned to take the instructions and source my own parts and build my own press. After thinking about how much time I have available, I opted for this kit. I'm glad I did! Everything you need is in the box and the instructions walk you right through the process. It is totally worth the price to not have to search through websites or local hardware stores to find all the parts you need. I'm looking forward to seeing how this works on my huge door project that I have planned.

-

Great Kit and Support

Review by Nick Barna

Rating:

I'm a professional furniture maker - I don't do a lot of veneering but this kit is perfect for my work. Easy to put together, great support, recommended!

-

Top Notch Product

Review by Jobe Reese

Rating:

This product is top notch. The kit is easy to put together. The packaging was very good and shipping was very fast. I really like the clean compact design. I am new to using a vacuum press and am very glad that I chose to buy this kit from Veneer Supplies.

-

Impressed by the Quality

Review by Dave Eggert

Rating:

I'm really glad I decided to go with the complete kit. I'm impressed by the quality of the components and really good assembly instructions. The wooden frame is quality Baltic birch and all the parts fit together very well.

The materials I used which are not included in the kit are varnish for the wooden parts, PVC glue and 4 rubber feet. That's it. Literally everything else is included.

Thanks for a great product.

-

Impressive Product!

Review by Steve Woodard

Rating:

This is definitely an A1 product. Every part you need is included in the kit and every part is of the highest quality. As for the assembly, if you follow the excellent instruction, you can actually assemble this kit with one arm tied behind your back. The reason I say this is because that's what I did, except that my arm was tied in front of me. When I ordered this kit, it was delivered, as always, quickly and well packaged. But the day after I ordered it, I had to have some emergency surgery to my left arm which left it in a sling and unusable for a few weeks. However, after about a week I couldn't stand it any longer so I I started unpacking and laying out the parts with my good arm.

I have a clamping table in my workshop which is fairly elaborate and I was able to assemble this kit using my clamping table and one arm. Not that this went quickly by any means, but still I was able to do it. I have just finished it and was able to test it using just a 3/4" piece of plywood, a piece of breather mesh, and a 4X4 polyurethane bag.

Even with this size bag the air was completely removed in less than a minute. I turned my compressor off and after 45 minutes, the vacuum indicator needle had not moved at all. I won't be trying to actually veneer anything until my arm is completely healed, but I can speak to the quality and power of this system. I would highly recommend this product to anyone. Now if only my arm will finish healing.

-

Definitely Worth It to Buy the Whole Kit

Review by Jim Brown

Rating:

Assembling this kit was fun! The directions are good, the components are of great quality, including the plywood parts. Definitely worth it to by the whole kit.

The only problem I ran into was my fault, trying to use old PVC adhesive. I didn't get a good seal and had to redo the tanks. Totally my fault. Don't make the mistake I did! Throw out the old stuff and buy a new can! Joe got me back on track soon enough.

Fast forward to now: just finished 9 good-sized panels. The venturi version worked like a charm for me! The JoeWoodworker.com site tells you everything you need to know, and these folks are the BEST. All questions answered, great communication throughout the purchase ... the absolute apex of internet commerce.

-

So Nice - I Bough It Twice

Review by T. Richard Harris

Rating:

I just bought my second kit from Joe because one just isn't enough in my shop. I find myself doing more veneer work than ever these days and this kit is flawless. I mean truly flawless. The instructions make is so easy and the box is packed with everything to get the kit put together in less than a two hours. As you probably already know - the customer service at this company is second to none.

-

Extremely Well-Designed System

Review by Jim Allen

Rating:

I love everything about this kit. Assembly was a breeze, and the instructions were detailed, thorough, and full of helpful tips to make things go smoothly. It's a great, compact system I'm sure that I'll enjoy using for years to come.

-

Assembly Was a Breeze!

Review by Dusty Mitich-Overby

Rating:

This was purchased by my boyfriend's father and we assembled it for him. He bought the non-Premium V4.

The instructions are very thorough and easy to read. All the parts you need are included, except glue, sandpaper, and tools. They list all the tools/extras you'll need in the beginning of the instruction manual, as well as a note about PVC cement. I also found it helpful that there was a parts list included. It was nice to be able see a picture of which parts they call for in each step. The instructions also split the assembly into sections with estimated assembly time per section. It took me and my guy about 2 leisurely hours to assemble and that accounts for the inevitable interruptions that come with having children.

I was quite impressed with the quality of the wood provided for the carrier. It was a nice solid birch and we left it unfinished. We only sanded it lightly as per the instructions.

As for shipping, the box was well packed and not a single thing was damaged. Shipping time seemed fair, about 4 days or so, though I don't know exactly when it was ordered.

We also didn't pressure test it as we don't have a compressor available to us. If I'm able to update the review, I will as soon as it's been put to use.

-

Happy Camper

Review by James Phetteplace

Rating:

Just used the V4 vacuum press that I had ordered a few weeks ago with the vacuum bag glue and other products I had ordered also. I am very happy with my purchase.

-

Exceptional Value for a Well Designed Product

Review by David Blehar

Rating:

I was a bit torn between the V2 and V4, ultimately went with the V4 thinking I was paying a bit for the convenience factor. I could not be happier with my choice. Forget about the convenience of not having to run out for additional supplies from the hardware store, the carrier components are something you would never reproduce at home without a CNC machine. Not to mention its made from nice Baltic birch plywood. It all makes for a nice compact little package that doesn't look like a bunch of scrap parts thrown together. The assembly instructions are exceptionally well done. I was taking my time and still done in under 2 hours.

As a side note, I got the Plus model which calls for 5.5 CFM at 90 PSI. I was a bit hesitant as my compressor is only rated for 5.3. No problems whatsoever. So if you've got the same California Air Tools compressor and wondering the same thing, you shouldn't have any trouble.

-

Praise for a Great Vacuum System

Review by Daniel Sutton

Rating:

I just sent Joe an email to thank him for shipping my system so quickly and to congratulate him on an incredible set up. I noticed that the last person to review this kit also got his shipment quickly and was positive about his assembly experience. There isn't much more I can add to those comments. I can only confirm that my press is already vacuuming my first project. You wont go wrong with this system as long as you buy the version that matches your compressor specifications.

The assembly is very easy. Its written well enough that a fool could put it together perfectly. The parts appear to be high quality and durable so I'm guessing I'll have many years of vacuum projects ahead of me. Can't wait to get some maple burl on my next side table. The vacuum filter is a nice touch too.

In closing I will say that doing business here is a pleasure and this kit is rock solid.

-

Spot-On Perfect

Review by Drew Miller

Rating:

I got my kit this afternoon. OK so what right? Well I ordered it yesterday! I finished building it about an hour ago and one of the first things I had to do was write this review. You wont fit better instructions anywhere but here. Everything went together absolutely flawlessly... I'm mean spot-on perfect. My vacuum press has been "charged" with vacuum for the last hour and it is so tight it hasn't even cycled back on once.

Top notch service. Flawless product. Incredible shipping. Superior quality. This site has it all. I could go on but I want to get something in the vacuum bag. You won't regret buying this system. A+++

-

Thanks Joe for making these products available!

Review by Ron Husbands

Rating:

This is a great product. I first thought to buy the kit and do it myself, but was a little too busy so I opted for the assembled kit. Good decision cause I know that everything would be tested first, in turn leaving me stress-free. I stained it and amazingly has fast and great vacuum. Extremely satisfying!

-

Great New Venturi System

Review by Kelly Scott

Rating:

This venturi vacuum system is terrific. I find that it evacuates the bag very quickly and gives a good 25" quickly. I used this on a 4x9 bag and once it does the initial evac, the cycles progress to increasingly longer intervals quite rapidly.

[Note from Joe: The ideal vacuum level for most veneering jobs in 21".]

-

So Much Easier

Review by Karen Vaughn

Rating:

I just got my system and I can honestly say that I'm proud to have this in my workshop. The quality and simplicity and overall appeal is evident. Such a great design and so incredibly powerful. I wish I'd had it a couple of years ago because it is so much easier to vacuum press a veneer sheet than to clamp it between two boards. Great job Joe!

-

Great Press, Excellent Value, Highly Recommended!

Review by Jeff Kusama-Hinte

Rating:

I generally make solid wood furniture but, occasionally, I have the need to apply shop sawn veneers. For years I have used clamps and cauls — which are always cumbersome and rarely deliver perfect results.

I purchased this press a couple of weeks ago and it has performed flawlessly. The device is well designed, very reasonably priced, has high quality components, and it is a pleasure to use. I am so happy that I chose a venturi pump model as the last thing I need is another motor humming away in the shop (my compressor is in a sound proofed room far from my bench); the only sound it makes it the release of air as it forms a vacuum.

The customer service has been fantastic — it shipped quickly, for a very reasonable fee, and my questions were answered promptly. I received one of the Pre-Assembled Prototype Kits so I didn’t assemble it myself, but I suspect that it would be a very straightforward process for anybody that was minimally mechanically inclined.

-

Works Great

Review by David Giasson

Rating:

Vacuum press works great and is easy to use. The delivery was fast and customer service great. I have enjoyed working with Joe and ordering the excellent products he offers.

-

Very happy with this product

Review by Alex Parker

Rating:

Fantastic tool. Works great, easy to set up and use. The “Basic” level venturi is plenty to operate a 2x4 foot vacuum bag.

-

Best Tool in My Woodshop

Review by Dylan Standridge

Rating:

I am very new to wood veneer and the process of veneering and buying this unit was the best choice I could have EVER made. This vacuum press kit is so well made and there is nothing to do. Just take it out of the box plug it in and go. This allows me to concentrate on the project and not the equipment!

This has become my new favorite tool in my woodshop!

-

Fantastic Kit with Impeccable Customer Service

Review by Anthony Myers

Rating:

I'll start by writing that Joe did ask me to write this review for his website but I don't mind doing it because a) the V4 system is incredible and b) Joe has been exceedingly helpful throughout this learning experiences. I'm actually writing this review while my third project is being pressed.

I ordered the premium 5 version and had it FedEx shipped to my house. The shipping charges seemed fair to me considering the weight and size of the box. The package arrived three days after I ordered but I know it shipped within 5 hours of putting the order through this website. That is impressive and it just goes to show what kind of business this is. I could not be happier with this kind of service.

Now on to the V4 review. Since my system is prototype (aka beta) model it was already assembled by Joe before shipping. I suspect the full assembly instructions will be impeccable. If you haven't seen his other vacuum press instructions then you should take a look because they are very well written. The V4 system is fairly compact considering what it does. It weighs less than 20 lbs but the handle grip is comfortable and balanced well on the system carrier. I first tested the unit by keeping the valve closed and letting it charge up vacuum and then cycle off. The system held with no leaks for 14 hours. After that I was just too excited to use it and couldn't wait any longer. My first project was with a 4x4 vinyl vacuum bag and the project was tiger maple veneer on a 3/4" thick piece of cabinet grade plywood. The V4 kit can be pre-charged with vacuum as I mentioned so the initial vacuuming of the bag is quick. The system required compressed air for less than minute to get the bag to 21" hg. My compressor did come on during the time but it ran for no longer than a normal "on" cycle.

The V4 system is run off of 12VDC which is a departure from the V2 system which was 120VAC. This has no impact on the performance of the vacuum press but I thought it was worth mentioning. Overall the system has a sort of grass roots feel. It kind of looks homemade but definitely better than most people could actually make on their own without knowing the complexities of what is going on with the various parts. The machining of the plastic carrier is outstanding and it appears that the parts of the system all fit perfectly on the carrier. The parts of the setup are good quality. For instance the brass fittings - they look better than hardware store Chinese brass parts. You can tell simply be the surface appearance of the brass. The hose assembly is rugged and the vacuum gauge appears to be stainless steel.

There is nothing I would suggest for improving this system. If you are thinking about getting into veneering then I highly recommend this system. You won't find better customer support anywhere else!