Categories

- Raw Wood Veneer

- Paper-Backed Veneer

- Edge Banding

- Vacuum Press Items

- Veneering Supplies

Shop by

Veneer Species

Veneer Supplies Newsletter

Veneer Information

Here's how we offer, measure, and ship the raw wood veneers on our website. ![]()

We want you to be completely satisfied with your raw wood veneer order. To assure this, the first step is to explain our inventory and product listing methods. Here is what you need to know (before ordering!) if you are unfamiliar with our website or have limited experience with raw wood veneer.

It is your responsibility to understand what is being purchased before placing an order. If in doubt, please contact us. We are happy to help with any questions.

Intended Use

Our veneers are suitable for indoor use only where the project is not exposed to water, excessive temperatures (including fire), or electrical hazards. We do not recommend or warrant our veneers as suitable for use as lamp shades or similar projects, or without the use of a suitable and stable substrate. Under no circumstance should our veneer be used for any type of structural application or other application where your safety, the safety of others, and surrounding property could be endangered by failure of the product.

Raw Wood Veneer Sheets & Lots

We offer raw wood veneer in two formats.

- Sheets are offered as individual pieces of veneer and are listed and priced by the sheet. The website listing will tell you exactly how many sheets are available in our real-time inventory, so you can order as many as you need.

- Lots are sold as bundles of veneer sheets. Lots are generally less expensive per square foot than veneer that is sold by the sheet. The square foot measurement of the lot is calculated by multiplying the number of sheets in the lot by the size of a single sheet of that veneer. The price shown is the cost for the entire lot.

Expected Loss - Very Important!

Do not order a veneer that is the exact size needed for a project! We will take every reasonable step to prevent damage from occurring to the veneer in your order, but please expect .5 to 1.25 inches of possible loss on the width and/or length of all veneers. This is to account for inevitable edge/end damage which often occurs in the handling and shipping process. Some loss may also occur from natural defects. This is especially true for burl veneers, which are exceptionally fragile.

Ends and Edges

There are no veneers on our website with an edge so straight that it could be placed against another veneer edge or other straight surface to get a perfect joint. You will need a veneer saw, veneer tape, and a few other items to successfully join two or more veneers together.

Measurements

- The width of long veneers with a slight taper is measured from the end of the sheet with the shortest width.

- The width of long veneers with a large taper is measured in the middle of the sheet, though we often provide additional measurement details in the description.

- Burl veneers that have very noticeable tapering or clipped corners will sometimes have a chalk mark in the picture that shows where the measurement was taken.

- When a chalk mark is not shown, it means that we have measured the full width and length of the veneer, inclusive of clipped corners. On those particular veneers, the square foot measurement will be slightly over-calculated since the measurements include the missing corners.

Real-Time Inventory

Our website will display the number of sheets or lots that we actually have in stock. This quantity is real-time. So if a veneer is listed as having four lots available and a customer orders one lot, then the product page will change to showing that we have three lots available.

Thickness

The thickness shown on the product page is approximate, since not all veneers in a bundle are exactly the same.

Sequential Sheets

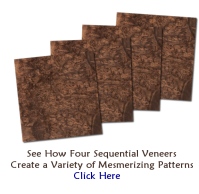

Unless otherwise noted in the product description, you will receive sequential sheets of veneer in your order. This is true of veneers sold in lots and those sold by the sheet. 'Sequential' simply means that the veneers are shipped in the order in which they were sliced from the tree. This will allow you to easily create bookmatch, quadmatch, or sunburst patterns for our project. Click on the image to the right to see what can be done with just four sequential sheets. Also consider checking out this short but informative article about veneer layups and jointing techniques on the JoeWoodworker website.

Grade

We use our own system for grading raw wood veneer using "stars". A one-star rating usually indicates a veneer suitable for backing and practicing. The best veneers get a five-star rating, which we also call "AAA" grade. Please keep in mind that our grading system is based on experience with the thousands of veneers we have offered over the years. The grade considers many factors including color, quality of cut, grain pattern, number of splits/voids, sheet size, and overall character.

Veneer Images

In a lot of 20 sheets from the same bundle, the top veneer may show a bark patch and the bottom veneer may be flawless. The pictures we show are always taken from the side of the bundle that has the most defects. This guarantees that you will receive the veneer in the condition as shown or even better. When photographing the veneers on this website, I do not use alcohol, water, or any other means of enhancing the grain or figure. I try to photograph the veneers as close to the original color as possible by shooting with proper lighting and by applying software-based color correction that is specific to our lighting source.

Color Variation

It is possible that pictures of some species will appear different on your computer screen or printer than what the veneer actually looks like. No two computers monitors will show colors identically. Some are brighter, some have more contrast, and others have differences in saturation or hue. We highly suggest researching the range of color within the species that is being considered for a project before making a selection, as we cannot be held responsible for variation in color. We have found that iPhones and iPads display reasonably accurate colors of our veneer photos.

Veneer 'Flatness'

Many of the veneers offered on this website have been pressed flat, which gives you a product that is ready to be placed directly into your vacuum press. There are three kinds of flatness.

- Truly flat veneers are those which are as flat as a sheet of paper.

- Veneers which are flat with some waves but can still be applied in a vacuum press without the use of a flattening agent.

- Veneers that need to be flattened and dried before they are placed in a vacuum press.

Each veneer on our website is marked as "Flat: Yes" or "Flat: No". Veneers marked as "Flat: Yes" may fall into either of the first two categories above.

We can not guarantee that a veneer will stay flat in your shop, and so it is important that you store the veneer correctly to prevent warping. Click here to learn more about the veneer flattening process.

Moisture Content

Our warehouse is climate controlled year-round to maintain 38% to 42% relative humidity, which is considered ideal for lumber and veneer since it results in a 7.2 to 7.8% moisture content in the wood. Some changes in moisture content should be expected in transit and when stored in your shop. This can cause flat veneers to become less flat. Please note that a veneer that feels brittle is not an indication that a veneer is "too dry". Some species are simply not as flexible as others and a lack of flexibility is not an indication that a veneer has not been sliced, processed, shipped, or stored improperly.

Veneer Packaging

Most small veneers are shipped between layers of cardboard flats that are placed in a suitably sized box. Larger veneers are rolled up and protected with paper cushioning. Even the most unruly veneers can be shipped safely. Each veneer is packaged using a nesting technique that we have developed during our many years of shipping orders. We call it "nesting" because it resembles the way a bird's nest wraps and softly protects its contents.

Safety Warnings

![]() California Proposition 65 Warning (Assembly Bill 1953) Regarding Wood Products: Wood products may expose individuals to methanol and wood dust, both natural components of wood. Warning: Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the state of California to cause cancer. Avoid inhaling wood dust, or use a mask or other safeguards for personal protection. Go to www.p65Warnings.ca.gov/wood for more information. We provide this warning based on our knowledge concerning the possible presence of one or more such chemicals, without attempting to evaluate the level of exposure.

California Proposition 65 Warning (Assembly Bill 1953) Regarding Wood Products: Wood products may expose individuals to methanol and wood dust, both natural components of wood. Warning: Drilling, sawing, sanding or machining wood products can expose you to wood dust, a substance known to the state of California to cause cancer. Avoid inhaling wood dust, or use a mask or other safeguards for personal protection. Go to www.p65Warnings.ca.gov/wood for more information. We provide this warning based on our knowledge concerning the possible presence of one or more such chemicals, without attempting to evaluate the level of exposure.

Additionally, the OSHA website states, "Wood dust becomes a potential health problem when wood particles from processes such as sanding and cutting become airborne. Breathing these particles may cause allergic respiratory symptoms, mucosal and non-allergic respiratory symptoms, and cancer. The extent of these hazards and the associated wood types have not been clearly established." Please visit https://www.osha.gov/SLTC/wooddust/index.html for more information.