Categories

- Raw Wood Veneer

- Paper-Backed Veneer

- Edge Banding

- Vacuum Press Items

- Veneering Supplies

Shop by

Veneer Species

Veneer Supplies Newsletter

I'm pretty sure this is one of the best edge banding trimmers available. It has two blades for cutting in either direction, and both blades can easily be reversed if one becomes dull. I've used one in my shop for more than a decade. The finger-friendly design of this edge trimmer makes it safe and easy to use. I've always maintained a "simple is better" approach to most veneering tools, and this item is no exception.

I'm pretty sure this is one of the best edge banding trimmers available. It has two blades for cutting in either direction, and both blades can easily be reversed if one becomes dull. I've used one in my shop for more than a decade. The finger-friendly design of this edge trimmer makes it safe and easy to use. I've always maintained a "simple is better" approach to most veneering tools, and this item is no exception.

Not for use with PVC or plastic edge bandings.

This tool is designed to trim fleece-backed wood veneer edge banding only.

Optional Item

We'll include a set of five replacement blades for $2.95 if you select this option above.

Note from Joe

The manufacturer's instructions included with this trimmer are not exactly great if you ask me. And some users have problems getting this tool to perform to their expectations because of those instructions. Here is what you need to know...

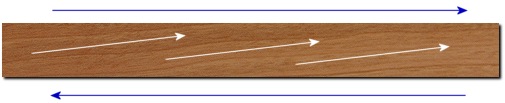

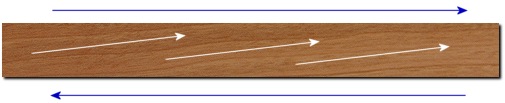

- To get a clean edge, pay attention to the direction of the grain. Edge banding typically has a somewhat straight grain, but it's rarely perfect. Look closely, and you may find that the grain has a slight angle. The best cut comes from sliding the trimmer in the direction of the grain as shown below. Cutting in any other direction will cause tear out.

The white arrows above show the slight angle of the grain direction.

The blue arrows show the correct direction that the flush trimming tool is used.

- Don't attempt to trim all the excess edge banding in a single stroke. Instead, take light cuts and remove no more than 1/8" of material with each pass. Removing less per pass is always better, and it doesn't add much time to the process. Once the edge banding is almost perfectly flush, take a final pass while pressing extra firmly downward on the tool. This should get it trimmed enough that a light sanding will make it perfect.

Be sure to check out the Edge Banding Guide on the JoeWoodworker website for more information.

Questions & Answers

Will this trimmer work on thick edge banding?

This trimmer will only trim wood veneer edge banding that is no thicker than 1/32".

Can I use this tool to trim paper-backed and two-ply veneer?

No. It will only work on fleece-backed edge banding (with or without hot-melt adhesive). A paperbacked veneer can be trimmed with a veneer saw, razor knife, or flush-cutting router bit.

Will it trim end grain?

This tool will trim the long grain of edge banding only. A chisel or razor blade is often a decent option for trimming end grain.

Would it be better to use a trimmer that cuts both sides at the same time?

I'm not impressed with those types of trimmers because one of the two edges will often end up with tear out and a jagged edge where the knife cuts against the grain. The knife should only cut in the direction of the grain. In the sample image below, a double-sided trimmer that is moved from left to right would leave a jagged edge on the lower side of the edge banding.

Will this cut the edge perfectly flush?

No. I would not take liability for saying that a tool does anything "perfectly", but it does do a very nice job of trimming that requires little follow-up work.

How much over-hang can this tool trim off?

The trimming process is completed by making multiple passes with the tool, so any amount of excess edge banding can be trimmed off. Each pass of the tool should remove no more than 1/8" of material. The final finishing passes remove a very fine sliver of material.

Product Reviews

-

Better Than Everything Else I've Tried

Review by Theo Walsh

Rating:

I'm glad I bought this trimmer for a kitchen remodeling job since it had about 150 feet of edge banding work with it. This tool is far easier to use than a razor knife. In fact it's better than everything else I've tried.

I used a few gentle passes and ended up with a very flush edges with no need for sanding. It makes edge trimming simple but it also does it quickly and safely. There is nothing on this website I wouldn't buy. The owner curates everything they offer and I suspect he uses most of these tools in his own veneering projects. You can't go wrong with this company.

-

Valuable Tool for Edgebanding Users

Review by Tim Morrissey

Rating:

This is a must-have tool for me since I do a lot of onsite restoration work. I keep the trimmer and some spare blades in my tool box at all times. Its much better to trim with this tool than with a router and flush trimming bit when working at a clean job site. I use this trimmer sideways and even upside down on some cabinetry jobs. No complaints whatsoever with this tool or anything I've bought from this supplier. Quality product and great customer service from a small family business.

-

Effective and Affordable Trimmer for Quick Work - Satisfied

Review by Edward Kirkpatrick

Rating:

This trimmer is simple and effective. I can do all eight edges of 2x3 ft panel in less than 5 minutes. Just have to pay attention to the grain direction to get a smooth cut. I never try to take off more than a sliver - Instead I do multiple repeat passes until its flush. It does not take much practice to get it right. Well worth the 12 bucks.

-

A Perfect Tool for Smaller Edge Banding Jobs

Review by Nicholas Huskins

Rating:

I have a dedicated ($25k+) industrial edgebanding machine in my shop but it is waiting for a replacement part to come in from Germany. We are in the middle of a big library job so the down time is a challenge. I’ve had this little handheld trimmer for years and I use it on job sites and even here in the shop for smaller stuff.

It works well which is why I bought a dozen more. I want one of these trimmers at the work bench of each my employee-craftsmen. They can be taught to use it effectively in less than 3 minutes... versus the machine which take more than an hour to learn to set up and get running. Of course the machine runs at light speed compared to hand trimming but for small jobs this tool just works perfect.

-

Not Recommended

Review by Peter Grossnickle

Rating:

This is not my favorite trimmer. It can be difficult to start at the edge of the strip/plywood and can sometimes dive deep and snag the edge banding. The banding itself was fantastic, but I wished I had paid more for a better trimmer—especially with wood pieces that I had fully cut to size and finished and then ended up having spots where the edge banding was damaged by the trimmer.

[Note from Joe: What the customer describes is almost always preventable. My guess is that he did not give enough attention to the grain direction. If he had contacted me about this issue, I would have gladly helped... especially because the solution is so simple. The image I created in the product description to show the importance of cutting with the grain (instead of against it) can not be over-looked. Failing to follow this tip can result in some tear out. This is true of every edge banding trimmer on the market (I've tried 8 or 9 of them in my shop). I wish the manufacturer of the tool would better describe it's proper use.]

-

Nice Tool

Review by Dmitry Noskov

Rating:

Nice little tool for edge trimming. For a beginner like me, it was very easy to use. Very easy to change or flip the blades when needed. It was shipped very quickly. Thank you.

-

Perfect Results

Review by Betsy Mendelsohn

Rating:

This novice wanted perfect results the first (and likely only) time she applied veneer for a home decorating project. The tool provided perfect results - be sure to follow the advice and slide with the woodgrain as the directions indicate. Now that I’m done, I’m giving the tool to a nonprofit woodworking school in my county.

-

Works Very Well

Review by Riki Heck

Rating:

As others have said, this works very well. It took me a bit of time to get used to it. My sense is that it works best when it there's only a small overhang, so I took to cutting anything big with scissors. But then it was perfect.

-

Follow the Website Instructions!!!!

Review by Mark Bowden

Rating:

I was not having much luck with the trimmer and was about to toss it in the back of my tool box. So I emailed Joe a message of complaint. He replied quickly with some instructions that were very helpful and trimmer works perfect now. I have no complaints what so ever. This is fine tool and a great company to buy from. You just gotta use the trimmer the right way!

[Note from Joe: I updated the instructions on the product description page so that everyone can understand the best way to use this tool. If you missed it, look at near the bottom of the product description on the main product page for two bullet points.]

-

This is a must!

Review by Jeff Schaefer

Rating:

Great tool for small jobs or when you don't have time or space to get out the router. Plus you can get replacement blades! If you don't have a shop or are working in someones home? This is MUST. Also, Joe is so helpful and a pleasure to deal with.

-

Nice, Simple, Easy to Use Tool

Review by David Britt

Rating:

Simple in design and use. No need to buy a more expensive product. I have used this on two-inch and one-inch edgebanding. Works a treat and simple to change blades.

-

Excellent tool

Review by John Barbor

Rating:

This little tool does exactly what it’s supposed to do.

-

Simple and Easy to Use

Review by Jennifer Chalmers

Rating:

You might not expect much from such a simple tool (thats what I thought) but it really does a nice job on the edges. I trim once with hard pressure and then I go back a second time with less pressure just to fine-tune the edges a bit. As long as you pay attention to the grain direction, there is no tear-out or any other kind of surprises.